The advances making upgrades to working dairies easy

Adding upgrades and automation to working dairies has changed from dreaded conversations into seamless realities for Australian dairymen using Daviesway’s key personnel and installation advances.

For some time, Daviesway has been quietly extending the life of dairies – often when they are in full production – adding automation, shortening milking times, and improving the information flow for dairymen throughout the country.

The key to those easy installations has been Daviesway’s experienced installation team on the ground, its fabrication workshop, a crack duo (for vision and pre-fabricated design) in Greg Lechte and Clint Dent, and the fact that everyone has access to one of the industry’s best project managers, Nico Polato.

Collectively, these factors have often saved weeks in installations, and have turned potential torment into triumph, allowing Australia’s dairy farmers to breathe easy when they make the decision to resuscitate their dairies...

Relationships key for dairy upgrade

Paul Mumford (left) with Daviesway DASCO's Brendan McGrath

Former United Dairyfarmers of Victoria (UDV) president Paul Mumford and his wife Lisa, decided to add significant automation to their dairy so they could retain their manager of 16 years, Aaron Thomas.

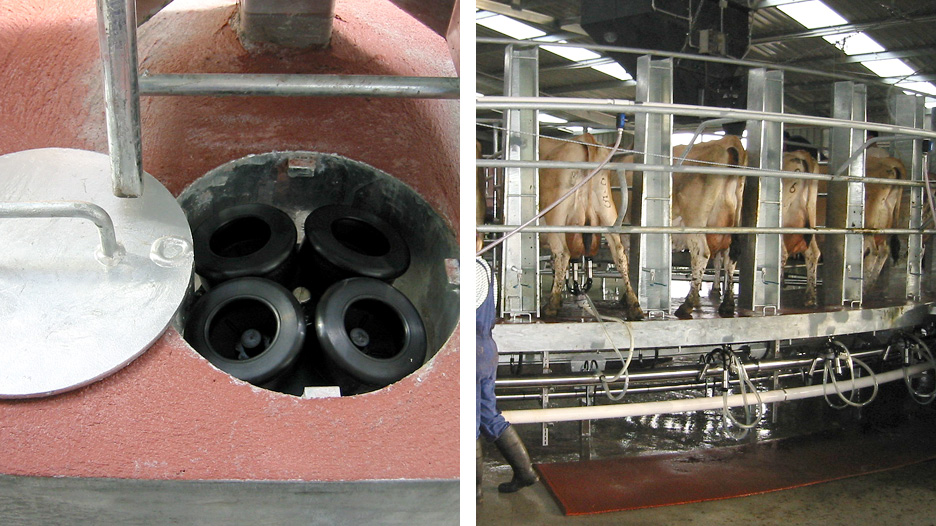

The 50-stand dairy on 405 hectares (1000 acres) at Won Wron in East Gippsland was 20 years old at the time; and while still spotless, its only automation was an automatic wash.

Paul and Lisa Mumfords dairy at Won Wron (East Gippsland), Victoria.

The challenges that drew the Mumfords to that juncture included Paul’s UDV commitments, which took him away 60-70% of the time. It had been hard to find staff, and milking took a lot of time in a completely two-man operation (which also demanded that Aaron was always there).

Aaron is passionate to the core about this 450-cow registered jersey herd (with some of his own cows in the group), but his exhaustion was becoming untenable … and it was impacting that strong passion.

It was time to change it.

Manager Aaron Thomas makes good use of the Easy Dairy touch screen computer system to check cow details on the go. It also allows operators to draft cows they are concerned about or add vet/health events.

Paul says, “Everyone has got the same problem. We struggled with balancing our farm labour unit, which meant we were essentially a full labour unit down all the time, and it was putting stress on absolutely everyone.

“We needed a completely integrated dairy operation to feed the cows appropriately, and we had to trust and use that technology to make some of those key decisions for us.”

Trust and technology

Paul says they had a strong relationship with the Daviesway team who serviced their dairy and supplied their DASCO chemicals. They had added full Milkrite clusters triangular shells and liners in 2020, and while their heart for the rest of the upgrade was with Daviesway, they did do due diligence and considered other options.

Daviesway modified the existing bail work to make sure the new equipment would fit and function. The CR-1 [Automatic Cup Removers] ram mounts are nestled in the bail work, with the controller, pulsator and position sensors all mounted up high (avoiding the ID, feed sensors, and equipment).

“For our own piece of mind, we looked at a relatively new 80-stand made by another company. But we didn’t love it.

“We knew the Daviesway tech boys, and we knew we didn’t have to train them on how our dairy worked, and how we liked things to be done.

“The whole upgrade took five weeks from start to go; during peak production, three weeks into joining.

“I was so sceptical beforehand, and I thought it was going to be a nightmare, but it happened pretty smoothly, and we didn’t really have to lift a finger to be honest.”

Paul and Lisa decided to shift their pulsation line from underneath the platform (where it had been exposed to moisture and erosion over time) to above the cows. They also opted for a claw drop/claw lift – actioned by the installation of new drop hoops – so that cups weren’t travelling across the top of the bridge, and the cups-on person no longer had to bend over to reach for each cluster. The claw drop/claw lift was a late decision, but it quickly become one of their favourite additions.

Paul says it made sense to let Daviesway drive the project.

“We didn’t have huge personal time to commit to it ourselves because we were understaffed and we were calving, so it was nice to give it to someone who knew the dairy and who knew how particular we were.

“The other reason we chose Daviesway was because they have always been part of our business, and we rely on that relationship. They do all our maintenance and all our repairs. We’d been discussing this with Brendan [McGrath, area manager] for a long time so he knew what we wanted, and how we wanted it done. Once we decided, we handballed the project to those guys.”

Daviesway DASCO’s Brendan McGrath discussing maintenance of the CR-1 ACR ram system.

What changed and what it means

The upgrades included installing CR-1 Automatic Cup Removers (ACRs), adding leg locators, an automatic teat spray wand, an automated feed system, auto drafting, and moving their pulsation line from underneath the platform (where it had been exposed to moisture and erosion over time) to above the cows. They also opted for a claw drop/claw lift so that cups weren’t travelling across the top of the bridge, and the cups-on person no longer had to bend over to reach for each cluster. The claw drop/claw lift was a late decision, but it has quickly become one of their favourite additions.

Mumford’s team member Luke Oliver enjoys the lighter Milkrite triangular vented mouthpiece liners and shells which worked well on the enterprise’s existing BouMatic claw. They were installed in 2020. Paul Mumford says, “They are so light, they milked out the cows better, and it was better for operator comfort.”

“Two years before this upgrade we’d put in the Milkrite clusters with the triangular shells and liners. They are so light, they milked the cows out better, and it was better for operator comfort,” Paul says.

“Then 12 months after that we had put cow collars on, which are solely for heat detection. Now, we have the ACRs, automated teat spray, an automatic draft and the automated feed system [off their NLIS ear tags through Easy Dairy].”

A Teat Wand Exact unit automatically teat sprays cows. Note that the cluster has automatically dropped down below the platform, so the cows have a completely clear entry and exit avenue.

A Teat Wand Exact unit automatically teat sprays cows.

Cow locators make sure cows stand ideally to allow easy access for milking, teat spraying, or general udder care. A deflector plate on the platform makes sure the cluster does not snag on the edge of the platform when it’s lifting to the operator. A plate locates the milk and twin-tube for consistent cluster alignment.

Momentous changes

For Aaron, the changes have been momentous. It has saved four hours a day which used to be spent milking.

“I’m back to enjoying it because I’ve got time to do what I’m supposed to do and that’s manage the farm and the cows properly,” Aaron says. “I was the main milker, so it was always me and someone else in the dairy twice a day, seven days a week.

For manager Aaron Thomas the changes and automation saved him four hours a day in the dairy and allowed him to re-claim his life.

Dairying is ultimately all about cow comfort and performance at Gelbeado Park Jerseys. Even though the upgrade was done during peak production – three weeks into joining – manager Aaron Thomas said the cows took it in their stride.

“The paddocks weren’t getting sowed or drilled through the day because I’d always have to go and get the cows. It meant I had a 10.30-11pm finish, and I’d be back up at 5am. I was running on the smell of an oily rag.

“Now, I’m either out on the farm doing more work or I can take my kids to swimming lessons. I’ve gone from doing 12-14 milkings a week down to four.

“Our second person, Luke Oliver, is now our primary milker. He does 10 milkings between Monday and Friday, and I do Saturday and Sunday. I get the cows in morning and night, and I’m always at the shed at the start of milking and at the end of milking if needs be. It’s great.”

Aaron says his daughters, Lexi, 9, and Evie, 6, have loved it.

“My family time personally has been the biggest benefit. The girls are busy with dancing and swimming, and before the upgrade I could never do any of that. Now, I take them to swimming lessons every Friday night.

Dairy entry area

Manager Aaron Thomas (left) usually brings the cows to the dairy and makes sure everything is running smoothly before he heads off to attend other jobs, leaving primary milker Luke Oliver (right) at the helm.

“A lot of owners wouldn’t spend a significant amount of money on an upgrade just to keep a manager happy. It was a big team effort. Lisa [Mumford] hasn’t milked so much over the last few years, but she can see the difference in me because of what we’ve done here.

“For Luke, this is his first-ever job. We were worried he wouldn’t adapt to the change, but he took to it like a duck to water. He’s young and it’s technology. It’s just been a winner.”

How it happened

The practicality of the changes within a working dairy were eased by Greg Lechte’s practical vision for what needed to happen, together with Clint Dent’s Computer-Aided Design, or CAD. Clint creates an accurately measured and detailed plan, allowing Daviesway’s Warragul manufacturing team to do much of the fabrication work in the workshop ahead of time. It essentially creates a “plug and play” plan.

The original rotating gland was serviced just before the upgrade, but otherwise it required no further upgrades.

In between milkings, the Daviesway team did a lot of the welding and fitting preparation for the additions that had been completed in the workshop.

Paul says, “The put the CR1 boxes in one day, something else another day. The first week was all welding and fabrication, the second week was installing and wiring, and the third week was bolting in all the bits and pieces.

“The fourth week was connection and commissioning. It was all pretty well sitting there installed, they just had to drop it in, test it, set the parameters, and change the milk hose.”

Aaron adds that watching the pulsation line (including a new filtered airline) go from underneath the platform in a single day to its new home up out of the water above the cows was something to see.

“It was pretty impressive. They cut everything out from under the platform, and had it all installed above the cows by 4pm that afternoon.

All components are installed within the cabinet bail profile, reducing any chances of cows injuring themselves during entry and exit. Rubber mats in both the entry and exits give the herd confidence and traction in a high traffic-flow area.

“There was two or three guys in here every day. Shane Mostert, Jarred Haw, Paul and Russel Dawson all need to be given some credit.

“It took me two weeks to trust the ACRs, but in the end you just have to have faith in them. When the upgrade got commissioned we were in peak production and I’ve never been able to take cups off as early as they were starting to come off, but the machines were saying they were milked out.”

Favourite things

Aaron says choosing his favourite addition is tough.

“All of it,” he smiles. “It all works in together. But the position drop is one thing I love. Once you’ve had it you wouldn’t not have it. And, the Easystart – all you do is take the weight of the cluster, and it starts. That’s definitely pretty cool.”

Paul and Lisa Mumford decided to add significant automation to their dairy so they could support their manager, Aaron Thomas, who has been with them 16 years. Aaron is equally passionate about Gelbeado Park Jerseys, but he was worn out.

Luke Oliver (pictured during a quiet moment as the herd gets to the dairy) had never milked a cow before he started working at Gelbeado Park Jerseys. Manager Aaron Thomas said he has taken to the cows like a duck to water.

He says two things have been highlighted for him as he considers the impact.

“I couldn’t go back to milking fulltime. I’ve got to do a week’s stint because Luke is on annual leave, which is fine. But, there is no way known I want to go back to morning and night milkings five or six days a week.

“I’ve got a life now. I’m not stressed, I’m not physically or mentally tired, I’m not angry. It’s just cruisy. It’s made our life and our business so, so much better.”.

Gelbeado Park’s original dairy was built in 2002 by Daviesway’ team. Twenty years later, it was given a new lease of life. While the upgrade took five weeks, during peak production, which wasn’t ideal for the cows, Paul Mumford says the reality surprised him. “I was so sceptical beforehand, and I thought it was going to be a nightmare, but it happened pretty smoothly, and we didn’t really have to lift a finger to be honest.”

Gelbeado Park’s original dairy was built in 2002 by Daviesway’ team.

From when the dairy was first commissioned over 20 years ago, it is clear the difference. Drop hoop and deflector plates installed, rams in the cabinet bail.

“The liner is the most important thing in the dairy – next to the cow and operator,” Nico said. “All the rest of the equipment is simply milk-path transport equipment. “We’ve seen the net results of this technology on so many farms in Australia, and around the world, and they speak for themselves. The improved teat condition, lowered SCC [somatic cell count] results, calm cows, less cup slippages … and the list goes on.”

NICO POLATO

DAVIESWAY SPECIAL DAIRY PROJECT MANAGER

Mobile: 0428 517 363

Email: nico.polato@daviesway.com.au

FREE CALL DAVIESWAY – 1800 600 269

See more Daviesway Dairy project information below

![]() Daviesway – Build Your Dairy Your Way

Daviesway – Build Your Dairy Your Way![]() Milkrite Triangular Vented Liners – Why are they so good?

Milkrite Triangular Vented Liners – Why are they so good?

![]() Dairy needs updating – Renovate or build?

Dairy needs updating – Renovate or build?

.