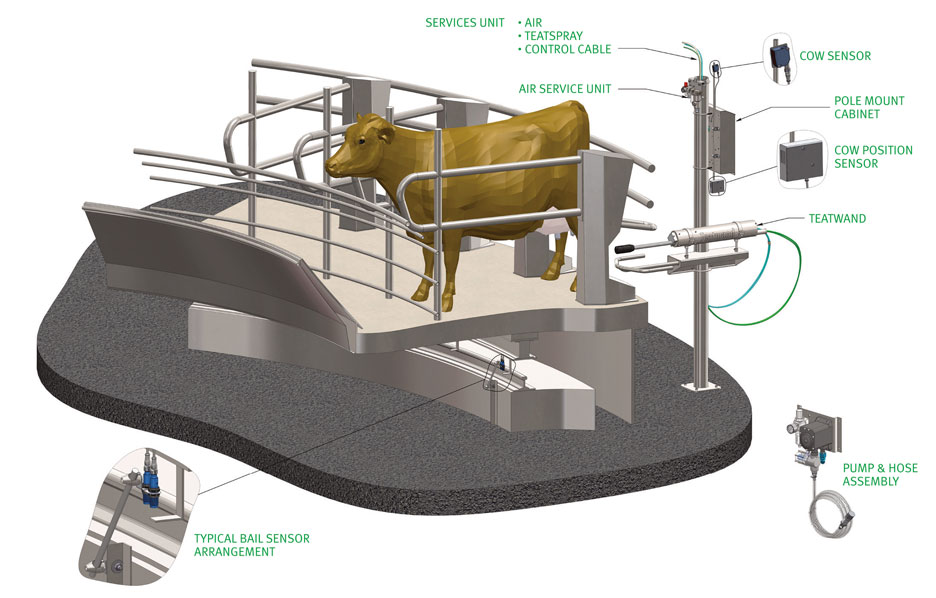

If you’re looking for automated teat spray solutions, we’ve got you covered. Daviesway is the largest Australian distributor for Onfarm Solutions which produces the Teatwand Exact.

If you’re looking for automated teat spray solutions, we’ve got you covered. Daviesway is the largest Australian distributor for Onfarm Solutions which produces the Teatwand Exact.

DESIGNED TO WORK HARD!

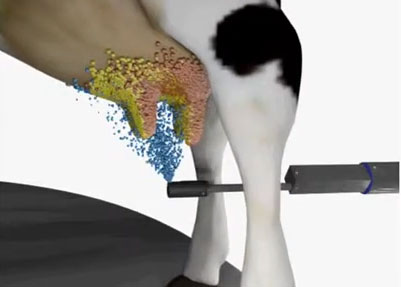

The Teatwand Exact is an Automatic Teat Spraying System suitable for any rotary platform type new or old running at speeds approaching 5.5 seconds per stall.

Designed to work equally well as a Pre-spray or Post-Spray solution. A Laser Position Sensor, Twin Nozzles and a Fully-Adjustable Touchscreen Control System allows excellent teat spray coverage with efficient usage of expensive teat sprays.

All Teatwand systems track the rotary platform speed and will automatically adjust the spraying sequence time to suit.

Contact Daviesway for more information

– free call 1800 666 269

FEATURES & BENEFITS

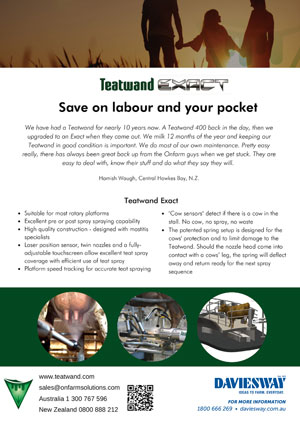

TWIN NOZZLES

TWIN NOZZLES

Thorough teat spray coverage of all four teats is achieved with the use of two independently controlled spray nozzles that extend under the cows’ udder as the rotary platform passes.

The Teatwand will accurately spray the teats before the cow leaves her stall, giving her the best chance to combat mastitis. The Teatwand controller can easily adjust the sequencing and spray volumes applied to cows’ teats.

CONTROL SYSTEM

The Laser Position Sensor measures where the cow is in the stall and provides data to the controller. This will automatically select the appropriate spray sequence providing accurate and fast total teat coverage without unnecessary use of teat spray.

The Stall Sensors are used to determine the direction of the rotary platform. This measures the speed of the rotary platform and activates a spray sequence. If the rotary platform is reversed the Teatwand system will not operate.

The Cow Sensor detects if there is a cow in the stall. No cow, no spray, no waste. Every application counts.

The Cluster Sensor* will detect if a cow is still milking as it comes past the Teatwand. The Teatwand system will detect that the cluster is still attached and will not operate.*Not applicable in some markets.

SAFETY MEASURES

Safety measures built into the Teatwand design ensure the best protection for the equipment and the cows.

The patented spring setup is designed for the cows' protection and to stop damage to the Teatwand system. Should the nozzle head come into contact with a cows’ leg, the spring will deflect and return to its original position ready for the next spray sequence.

Each Teatwand system has an Air Filtration Unit to regulate and filter the compressed air used to operate the system. An isolation valve also exhausts all compressed air from the Teatwand systems, ensuring the safety of staff and service people during maintenance procedures.

The rotary platform can be stopped and started at will without affecting the Teatwand system operations.